Wire Rope Pulling Hoist

- Newly

- Safety

- Reliability

- Durability

What is a tirfor winch?

The tirfor winch, also called a wire rope puller, is a versatile tool that can easily lift, pull, and tension. The machine is designed with safety in mind, boasting a high safety factor and a durable casing crafted from premium aluminium alloy die-casting. The steel wire rope is equally impressive, boasting a high breaking force and enhanced wear resistance with variable lengths available for order, ranging from 800 kg to 5400 kg. With its adaptability to various settings such as factories, construction sites, and transportation venues, it is the ideal device for equipment installation, cargo lifting, object fixing, lashing, and traction. It excels in challenging locations with limited work areas and no available power sources.

How does a tirfor winch work?

The working principle may be described as “ hand-to-hand”, like a sailor pulling on a rope. When one hand pulls the rope, the other hand holds the rope tightly to control the direction of the rope. The two hands represent the 2 jaws in the cable puller winch. The two jaws hold the wire rope tightly without damaging the wire rope. When pulling forward, the two jaws pull the wire rope alternately and alternately hold it when lowering. The effort is transferred to the jaws by two levers. One is for forwarder operation and the other is for reverse operation, which ensures the load is held securely.

How to operate a Tirfor machine?

Easily operate the griphoist by pressing its body and releasing the handle until you hear a satisfying “click,” indicating that the jaws have opened. Simply pass the steel wire rope through the hole at the end of the puller to the length you need. To clamp the wire rope in place, press the handle again and voila! The winch is ready to go.

After hooked the load, please follow the below 3 steps:

- Pull the forward lever: lift, (forward), tension

- Pull the reverse lever: drop, (reverse)

- Braking: Regardless of “lifting” or “lowering”, during the loading process, stop pulling the handle to achieve braking so that the loaded object stays at any position.

Tirfor Jack, the Right Tool for your Job!

The wire rope pulling hoist is widely used in construction, public works and civil engineering. They are used to move and position formwork horizontally or vertically, to position sections of precast concrete beams.

The manual wire rope puller is widely used in electricity and telecommunications. It is used for positioning transformers, tensioning underground and head cables, installing and moving wires, and guying operations.

The wire rope lever hoist is widely used in mines and quarries. It’s used for handling and positioning equipment and underground machinery or tensioning conveyors.

Characteristics of the Wire Rope Pulling Hoist

- Advantages of the Tirfor winch

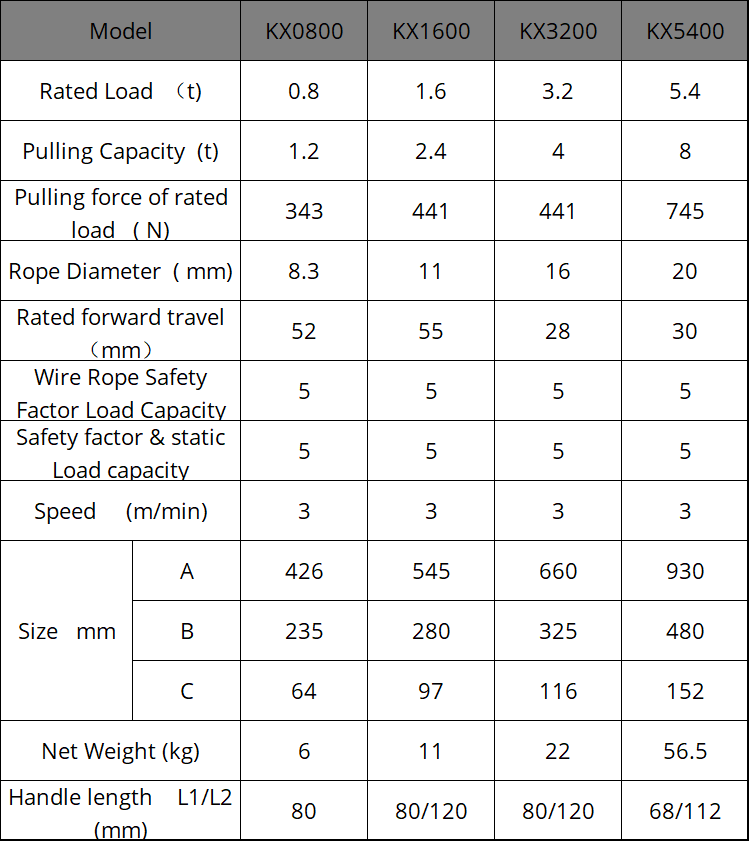

- Data Sheet

- Winch Quality

- Simple structure and powerful functions. Fast and easy installation, the wire rope can be operated easily. It can work continuously, just transferring the lever from one handle to the other to control the forward or backward of the wire rope. The puller can work in any position horizontal, vertical or angled.

- The length of the wire rope is not limited. Our standard length of the wire rope is 20M and custom length is available.

- Safe and reliable. The jaws and connecting axle have been quenching treatment and the modules have been electroplated. Every winch has passed the 1.5 times tensile test.

- Overload protection. Each winch has a shear pin in the forwarder handle. When the lifting exceeds 25% of the rated load, the safety pin will break to prevent overweight. Liftpand has packaged two pins in each handle for customers to maintain.

- Loading positioning accurate to “mm”. Whether lifting or lowering, the load is permanently controlled with the utmost precision. The load is spread between the two jaw blocks when the operation stops.

- Body: High strength 104 aluminium

- Surface treatment: Spray, the standard for sand grey, colour can be customized.

- Jaw blocks:40Cr after quenching, suitable hardness, not damage the wire rope and can ensure safety.

- Wire rope: The standard length is 20M in hot dip galvanized. Structure 6✖19W+IWR-8.3MM. Strength 1770Mpa.

- Wire rope hook: Standard American eye hook, material 35CrMo, high tensile strength. Swivel hooks or European hooks are available.

| Capacity | Quantity | Dimension of the Plywood case | Net Weight | Gross Weight |

| 0.8T | 30PCS | 1100x1100x800 | 437KGS | 470KGS |

| 1.6T | 20PCS | 1100x1100x810 | 530KGS | 571KGS |

| 3.2T | 10PCS | 1100x1100x710 | 483KGS | 514KGS |

| 5.4T | 5PCS | 1100x1100x680 | 483KGS | 515KGS |