Ratchet Lever Chain Hoist

Lightweight and strong load

Operate and install easily

Simple Introduction

Manual-operated chain lever hoists have the features of safety, durability, reliability; good performance, easy maintenance; small size, lightweight, easy to carry; small hand force, high efficiency; perfect structure, beautiful appearance and so on.

It’s easily used for lifting, traction, lowering, calibration and other operations by hand ratchet.

Both chain hoists and lever hoists are called manual hoists, which use manpower to lift heavy objects, and the operating handle must not be arbitrarily lengthened. During operation, the rest of the handles should be allowed to move freely without jamming. The hoist with the appropriate ton must be selected according to the size of the load.

The lifting capacity of the portable ratchet hoist is generally 0.25T-9T. They are used in shipbuilding, electric power, transportation, construction, mining, post and telecommunications and other industries for equipment installation, item lifting, machine parts pulling, etc.

In addition to being used alone, the lever hoist can be combined with a plain or geared trolley as a travelling type. It is suitable for the monorail overhead conveying system, hand travelling crane and Jib crane.

Models of Panda lever block

Chain lever hoists can be divided into two types: ordinary chain lever hoists and mini lever hoists. According to the different shell materials and properties, the lever hoist can be divided into aluminium alloy lever hoist, alloy steel lever hoist and so on. According to the different application scenarios and lifting capacity, the lever block can also be divided into two types: heavy-duty lever block and standard lever block.

Technical advantages of the Lever Block

Key parts of the lever block

The main components of the chain lever hoist are gear casing, lifting sprocket, drive shaft, load chain, side plates, top and bottom hooks, brake seat, friction plate, ratchet, pawl, change over gear, selector lever, lever handle cover, hand wheel and so on.

Standard lifting capacity of lever hoist

The standard capacity of the lever block is 0.75T 1.5T 3T 6T 9T. The lifting height is 1.5M.

But usually, in the market, we can always see 1T and 2T, sometimes 5T lever hoist.

1T is the same hoist body with 0.75T, just change the load hook to 1T.

2T is the same hoist body with 1.5T, just change the load hook to 2T.

If 5T, then we can use 6T to change the sticker.

Lever block inspection

Every lever hoist must pass the inspection dynamic load 1.25 times, static load 4 times.

Different operation way of VA and VL

The VA type is free chain fall, which means when no load, we can adjust the load chain freely.

The VL type has a special retaining ratchet pawl design. Adjust the ratchet pawl and pull out the brake cover, then you can adjust the load chain freely. After done, should push the cover back and lift up and down.

VA Ratchet Chain Block

- Feature

- Data Sheet

- Explosive View

- The most popular and economical series.

- Meet European Standard EN13157. Every lever block in our factory has the safety coefficient of at least 4:1. It’s tested to withstand 1500 cycles with 110% of the rated capacity.

- Industrial powder coating provides a long-lasting finish in terrible environments.

- Forged and heat-treated load hooks with safety latches meet European standard in safety factor 4:1.

- Double pawl brake system holds the load safely during operation.

- Sealed needle bearing allows low handling force and more efficient.

- The chain stopper protects the body.

- Alloy steel G80 load chain is in safety operation and durability.

- Ergonomic steel handle with rubber grip provides non slip.

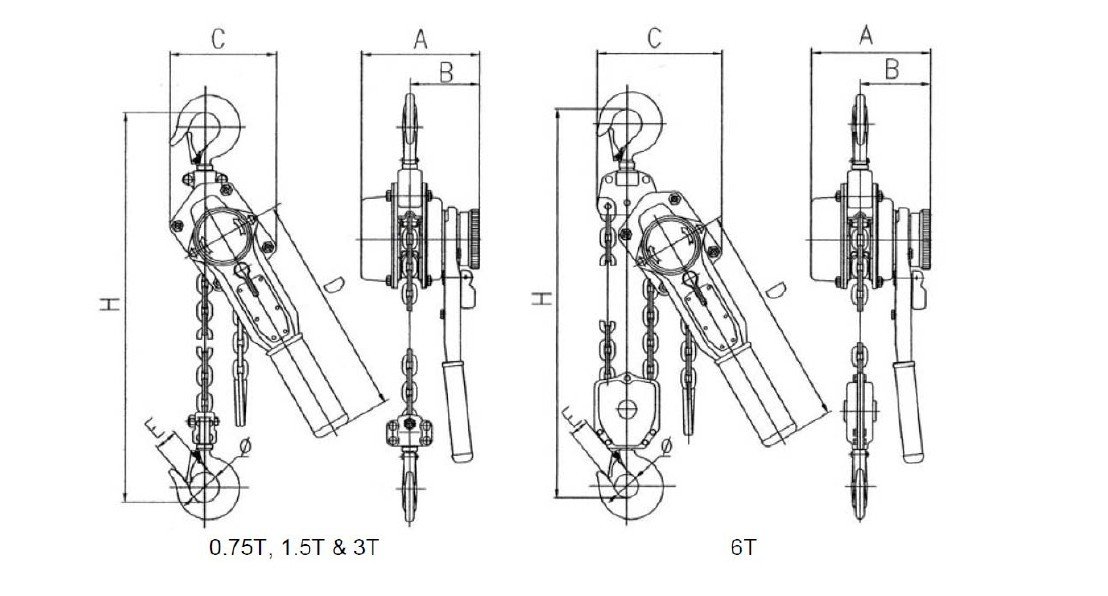

| Model | VA075 | VA150 | VA300 | VA600 | VA900 | |

| Capacity ton | 0.75 | 1.5 | 3 | 6 | 9 | |

| Test load kg | 950 | 1870 | 3750 | 7500 | 11250 | |

| Standard lift m | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Force of full load N | 250 | 310 | 410 | 420 | 420 | |

| Load chain diameter mm | 6 | 8 | 10 | 10 | 10 | |

| Falls of load chain | 1 | 1 | 1 | 2 | 3 | |

| Min headroom H mm | 310 | 385 | 460 | 600 | 860 | |

| Length of handle mm | 308 | 408 | 418 | 418 | 418 | |

| Net weight kg | 6.4 | 11.5 | 20.3 | 30.5 | 49.8 | |

| Shipping weight kg | 6.7 | 11.8 | 20.8 | 31.5 | 51.8 | |

| Dimensions mm | a | 149 | 171 | 204 | 204 | 204 |

| b | 89 | 102 | 114 | 114 | 114 | |

| c | 128 | 145 | 203 | 243 | 340 | |

| Φ | 37 | 45 | 55 | 65 | 75 | |

| e | 29 | 35 | 44 | 50 | 54 | |

Features:

- Adopt Japan technology

- Special retaining pawl design for easy idling operation.

- Fine apperance and lightweight with compact size.

- Waterproof, shock-resistant gear cover and brake cover.

- Mechanical brake:safe, trouble-free, and rust-resistant.

- Forged and heat treated load hooks with safety latches meet European standard in safety factor 4:1.

- High-tech load chains are made by 20 Mn2, one of the world’s strictest standards. This is the special heat-treated load chain of Grade 80.

- Ergonomic steel handle with rubber grip provides non slip.

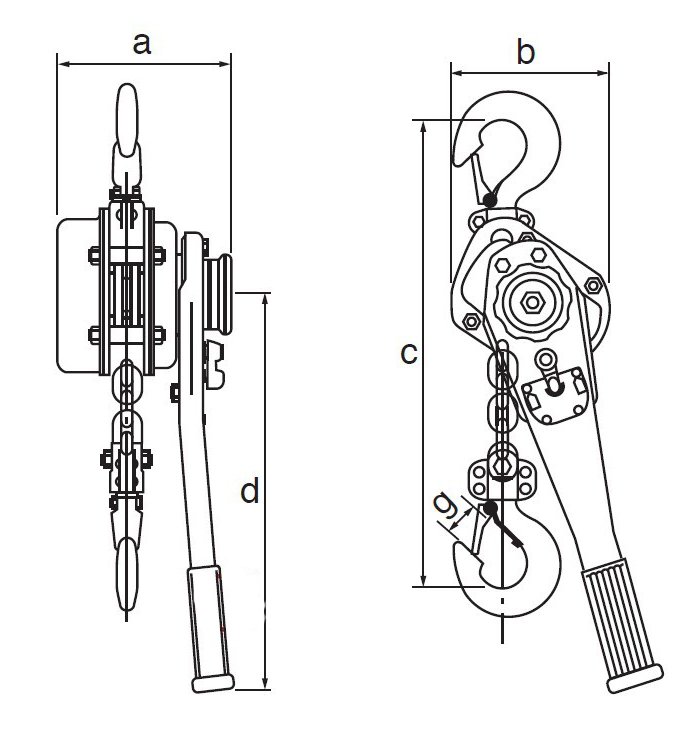

| Model | VL080 | VL100 | VL160 | VL320 | VL630 | VL900 | |

| Rated Load ton | 0.8 | 1 | 1.6 | 3.2 | 6.3 | 9 | |

| Test load kg | 1000 | 1200 | 2000 | 4000 | 7800 | 11250 | |

| Standard lift m | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Min headroom mm | 295 | 325 | 350 | 425 | 565 | 680 | |

| Force of full load N | 206 | 226 | 265 | 373 | 382 | 392 | |

| Load chain diameter mm | 6 | 6 | 8 | 10 | 10 | 10 | |

| Net weight kg | 6 | 7.2 | 9.8 | 16.6 | 27 | 47.3 | |

| Shipping weight kg | 6.3 | 7.5 | 10.3 | 17.2 | 28 | 49.3 | |

| Dimensions mm | a | 146 | 146 | 161 | 195 | 195 | 195 |

| b | 119 | 126 | 146 | 180 | 243 | 318 | |

| c | 295 | 325 | 350 | 425 | 565 | 660 | |

| d | 256 | 256 | 368 | 368 | 368 | 368 | |

| g | 27 | 30 | 34 | 43 | 47 | 67 | |

Related Product

Company service and technical support

- Samples can be offered by express. Costs will be reduced in orders.

- Our parts library can ensure timely and enough spare parts. Some free-wearing parts can be offered according to order details.

- Our guarantee is 1 year for free maintenance. Our technical and quality department is strict with every after-sales question.

- Training can be provided, such as design, customization, installation and after-sales use.

- OEM is welcome.

- Completely quick feedback