Description of the main parameters

- The fork of the manual pallet stacker can be adjusted to a width of 340-770mm, a length of 900mm, and a height of 1.6m

- Generally speaking, the international standard manual hydraulic stacker has three load capacities of 1.0t-2.0t-3.0t.

- The fork of the manual stacker is at the lowest point with a height of 90mm

- I-Beam, U-Beam, and Bending C-Beam can be selected for the doorpost.

- The wheel material of the hand pallet stacker include nylon, polyurethane, rubber, etc

- Special function hydraulic manual stacker includes double post stacker and widened stacker. The double post stacker can be made 3m high. The fork of the widened stacker can reach 1.4m.

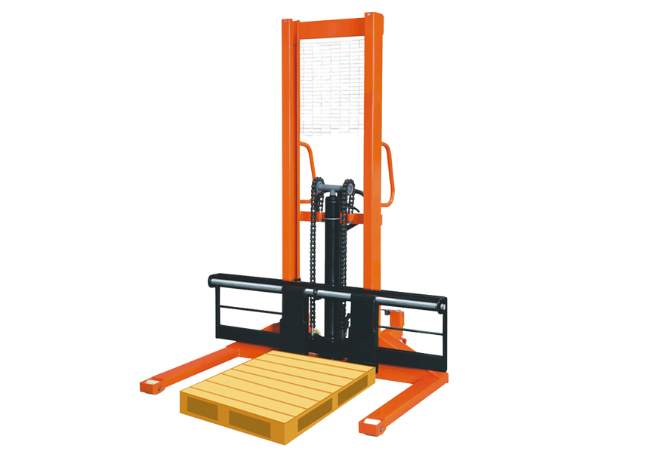

Material Handling Equipment Family Member - Manual Pallet Stacker

Manual pallet stacker is a pollution-free, non-powered loading and unloading equipment, which has the characteristics of compact structure, flexible transportation, simple operation, and small turning radius. As a materials handling equipment, pallet stacker is suitable for cargo handling and stacking in factories, workshops, warehouses, stations, docks, etc. It is more suitable for those places with fireproof and explosion-proof requirements such as printing workshops, oil depots, docks, warehouses, etc. If combined with pallet packing, containers, etc., unitized transportation can be realized, which effectively reduces the collision, scratches and stacking area of parts, reduces the handling workload, and improves the handling efficiency. Single gantry structure design of the manual pallet stacker, small turning radius, suitable for machinery manufacturing, paper making, printing, handling, logistics and other industries.

Features and advantages of our manual pallet stacker

- The mast frame of our manual hydraulic stacker is made of heavy-duty “C”-shaped steel column steel, which is cold-formed. Stronger, safer, flexible to move, easy to operate and labor-saving.

- The oil cylinder of the manual pallet stacker adopts high-precision grinding tube, wear-resistant seal, and integrated valve core, which is convenient for disassembly and maintenance; the pressurization method adopts pedal type and pressure handle type, the lifting speed is stable, and the safety is greatly improved.

- The advanced plastic spraying process is adopted to improve the appearance of the product and increase the durability of the manual hydraulic stacker.

- The manual hydraulic stacker is a pollution-free manual pallet stacker, which has the characteristics of dexterous transportation, flexible operation, and small turning radius.

- Manual hydraulic stacker is light in weight and easy to operate; low in price, economical and practical; simple in structure and low in maintenance cost.

How to use the manual pallet stacker

- Toggle the oil pressure switch to keep the fork in a low position, carefully move the hand pallet stacker to the shelf and keep it vertical to the shelf.

- Adjust the width of the fork of the pallet stacker to fit the pallet.

- Repeatedly press the handle or the pedal to raise the fork to the desired height to ensure that the fork of the manual hydraulic stacker can easily fork into the pallet.

- Raise the fork again until the pallet is lifted from the rack.

- Slowly move the goods out of the rack, toggle the oil pressure release device, slowly lower the goods, and at the same time ensure that the forks do not touch obstacles during the lowering process, and then slowly move the hand stacker to the required position.

- After use, do not put the manual pallet stacker on the ramp, and perform the brake gear.

- Data sheet

- FAQs

| Capacity (kg) | 1000/2000/3000 |

| Fork length (mm) | 900 |

| Width fork adjustable (mm) | 320-740 |

| Lifting height (mm) | 1600 |

| Fork wheel(mm) | φ75×70 |

| Steering wheel(mm) | φ180×50 |

| Qty/40 feet container(pcs) | 75 |

-

Our pallet stacker door posts have C-beam, U-beam, I-beam. The manual hydraulic stackers we export are generally made of C-beam because the performance is more stable.

-

The material of the manual pallet stacker wheel can be met according to the needs of customers.

-

The width, length, and lifting height of the hand pallet stacker fork can be customized according to customer needs, please send demand to discuss.

How to choose a manual hydraulic stacker

There are a number of things to consider when choosing your manual pallet stacker:

- Size of load – What weight will manual pallet stacker need to handle? What are the sizes of the pallets you’ll be moving? You need to ensure the hand pallet stacker you select is competent to the job.

- Required lift height – How high up will the pallets need to go? Where are you moving the loads?

- The area you’re using the manual pallet stacker – Are there any restrictions where you’re planning to use the manual pallet stacker? Are there overhead obstructions –beams, lamps, etc? Is there big enough to operate?

In the first case, the fork of the manual pallet stacker cannot reach the maximum height. The reason for this is insufficient hydraulic oil and the solution is to add hydraulic oil.

In the second case, the forks of the manual hydraulic stacker cannot be lifted. There are several possibilities:

1. There may be no hydraulic oil, this only needs to be refueled;

2. It may be that the hydraulic oil is impure. Release all the hydraulic oil in the cylinder and replace the hydraulic oil again;

3. It may be that the adjusting nut is too high. Open the unloading valve to increase the test pressure of the adjusting nut.

4. There may be air in the hydraulic oil. It is sufficient to remove air from the hydraulic fluid. The exhaust method is to open the unloading valve, and then pull the handle to reciprocate up and down several times.

First, the piston rod or cylinder is damaged and deformed due to the goods being biased to one side or overloaded, and the piston rod or cylinder needs to be replaced;

Secondly, it may be that the fork frame of the manual stacker has been in the elevated position for a long time, and the piston rod is exposed and rusted, making the piston unable to move. The solution is to lower the forks of the hand stacker when not in use, and pay attention to the timely lubrication of the piston rod.

Third, it may be that the adjusting nut is in the wrong position, the solution is to adjust the nut.

- When loading goods, do not overweight or eccentrically load.

- Do not drive on slopes or stay on slopes.

- When entering and exiting the elevator, the manual hydraulic stacker is first in, and the people are in last. It is guaranteed that the people are out first and then the hand stacker out.

- Pay attention to a load ratio problem of the manual stacker, and avoid the cargo center moving up and overturning.

- Forbidden to operate manual pallet stacker after drinking.

- Forbidden to load people using the manual hydraulic stacker.

The maintenance of manual hydraulic stacker is to reduce wear as much as possible. Proper maintenance of manual hydraulic forklifts will prolong the service life of manual hydraulic stacker. During maintenance, the oil, air, and lubrication functions are mainly checked. At the end of each shift, the forks of the hand hydraulic stacker should be unloaded and lowered to the lowest position. Regularly (such as once every six months) open the oil drain screw hole to check the oil level. The newly injected oil into the rubber container should be 5mm below the liquid level, and the container must be at the lowest position when adding oil. When replacing the seal of a manual hydraulic stacker, air may enter the hydraulic system, put the joystick in the lowest position, and then swing the handle more than a dozen times, lubricate the moving parts with motor oil or lubricating oil.