INTRODUCTION OF THE MANUAL TROLLEY

Manual chain hoists boast simplicity in operation and portability, making them an indispensable tool across various industries including manufacturing plants, mining operations, construction sites, ports, shipyards, and warehouses, to name a few. However, the functionality of a hand chain hoist, in isolation, is limited to vertical lifting operations. This constraint poses a challenge for tasks that demand a wider range of material handling and transportation. To bridge this gap, the integration of a monorail trolley system becomes imperative. The monorail trolley, which can be suspended from various types of small cranes or mounted onto fixed I-beams, complements the monorail trolley hoist to facilitate a comprehensive range of lifting operations, thereby enhancing efficiency and versatility in material handling tasks.

Monorail trolleys are categorized into two types: the hand-pushed trolley(GCT) and the geared trolley(GCL), with capacities ranging from 0.5T to 50 T. The geared trolley operates through a hand chain drive, whereas the push trolley utilizes manual force for the movement of suspended loads. Both trolleys have the ability to traverse the lower flange of I-beam tracks smoothly. Additionally, the wheel flange spacing can be adjusted according to the width requirements of the I-beam tracks. By suspending a manual hoist beneath the trolley, it can be deployed on straight or curved monorail overhead transport lines, or on manual single-girder bridge cranes. This makes them highly versatile and widely applicable in factories, mining operations, docks, shipyards, warehouses, and machine rooms for equipment installation and material handling. They are especially advantageous in locations without a power supply, offering a superior solution for equipment maintenance and repair.

The monorail trolley features a compact design with minimal installation dimensions and is composed of several components including the left and right side plates, suspension beam and lifting ring, hand chain wheel, and rotating axle. The manual pulling of the hand chain causes the rotating axle to spin, which, through the interplay of gears, drives the wheels of the trolley to move along the track. The trolley can be adapted to different I-beam widths by adjusting the spacing with washers. The left and right side plates of the monorail trolley are connected through hinges. Under the influence of gravity, the trolley autonomously adjusts its height to ensure that all four wheels are evenly loaded, thus ensuring safe operation and ease of maintenance.

CORRECT USE OF THE MANUAL TROLLEY

The manual trolley boasts high transmission efficiency and requires minimal manual pulling force. Moreover, it is capable of navigating curves with relatively small turning radii. When operating the monorail trolley, it is essential to heed the following guidelines:

- Never overload the manual trolley beyond its rated capacity.

- While the monorail trolley is hoisting heavy loads, it is strictly prohibited for personnel to walk or work underneath the suspended items.

- When lifting heavy items with the monorail trolley, ensure that the centre of gravity is within the plane of the I-beam’s web. Do not lift if this condition is not met.

- During operation, the pulling force applied to the hand chain should be in the plane of the hand chain wheel, and the chain should not be pulled at an angle.

- If abnormal pulling resistance is encountered when operating the monorail trolley, do not yank forcefully. Instead, immediately cease operation and investigate the cause.

- Regularly lubricate the gears and the track surface with lubricating oil, and simultaneously check for any loosening of fasteners.

- The geared monorail trolley operates with the I-beam as its support structure. Therefore, I-beams that are deformed, twisted, cracked, or otherwise non-compliant with standards, or have any other defects, should not be used for the monorail trolley.

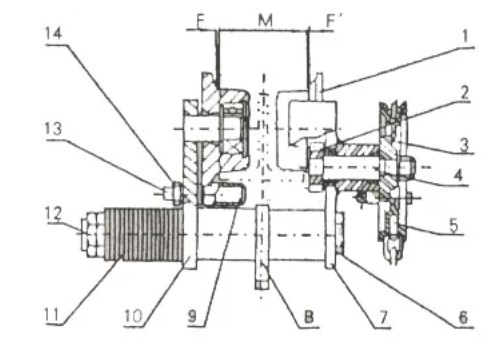

STEP BY STEP TO INSTALL THE MANUAL TROLLEY

- Fasten with nut after hanging shaft (6) passed the left (10) and right (7) side plates.

- The ring (8) should be in the center of the shaft (6). There should be the same washer quantity from the ring to the left and right side plates. Chain blocks, lever hoists or other lifting equipment can be hung on the lifting rings to transport goods.

- Spare washers(11) are available to accommodate different beam widths(M).

- Pre-tighten the nuts(12) when installing the trolley with the beam. After the wheel (1) is on the beam and adjust to the right width, then tighten the nut. The nuts must be locked each other.

- After the monorail trolley is installed, the gap (F) between the roller sleeve (9) and the bottom surface of the track must be adjusted to make it reach the specified value. First, loosen the nut (14) and move the roller sleeve shaft (13) to make the gap reach the specified value before tightening the nut.