Simple Introduction of The Electric Wire Rope Hoist

The wire rope electric hoist is light and small lifting equipment. It has the advantages of compact structure, lightweight, small volume, strong versatility of parts, and convenient operation.

The electric wire rope hoist can be installed on the I-beam alone or matched installed on an electric or manual single-girder, double-girder, cantilever, gantry and other cranes. With a little modification, it can also be used as a winch, which can meet the requirements of general occasions. Therefore, it is one of the most commonly used lifting equipment in factories, mines, ports, warehouses, freight yards, shops, etc. It is a must for improving labour efficiency and working conditions.

Liftpand cd1 electric hoist uses the conic rotor brake asynchronous motor with large power. It adopts a three-stage fixed-axis helical gear transmission structure, and the gears and shafts are made of heat-treated alloy steel. The cover is made of high-quality cast iron, tightly assembled and well-sealed. The limit position with up and down stroke protection can cut off the main circuit in an emergency and ensure the safe operation of the electric hoist. The electrical components have a long service life and are more reliable in use. GB1102-74〔6*37+1〕type wire rope is adopted to ensure durability and durability. And there are two ways of handling control operation and wireless remote control.

Standard of Liftpand CD1 Electric Wire Rope Hoist:

Lifting Capacity:0.5T、1T、2T、3T、5T、10T、20T

Lifting Height:6m、9m、12m、18m、24m、30m

Working Rate: M3

Protection Class: IP44 IP54

Lifting Speed: 8m/min [10T: 7m/min]

Loading Persisting Rate: FC25%

The non-standard electric wire rope hoist can be customized. Lifting height: 6M~100M. Voltage:220V~660V.

Working Conditions:

CD1 type electric hoist is suitable for working in an environment with a temperature of -20°C-40°C, relative humidity of ≤85%, an altitude of less than 1000m, no fire, explosion hazards, and corrosive media. It is forbidden to transport molten metal, which is toxic and flammable and explosive items. The applicable power supply is AC three-phase, 50Hz, 380v; the working type of this product is medium-level, and the rated lifting capacity must be reduced by 20% when the working level of the mechanism in use is increased by one level.

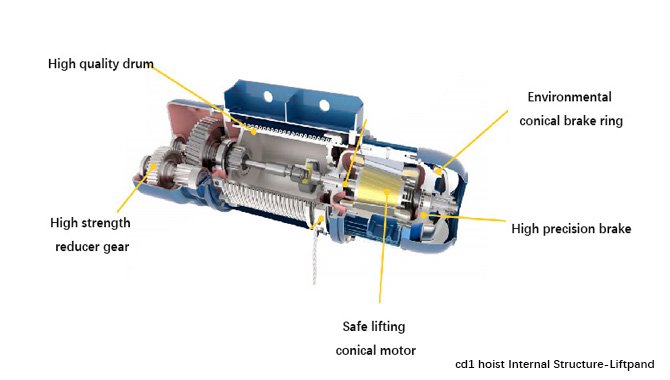

Main Parts of CD1 Wire Rope Hoist

The main structure of CD1 wire rope electric hoist(lifting framework, travelling framework, and electric apparatus control system):

Operation reducer, operation motor, lifting motor, lifting reducer, drum, drum cover, hook, control, coupling, contactor, power cord, limiter, pendant control, rope guide, steel wire rope.

The motor adopts a conical rotor motor, which integrates power and braking force. Better quality from Nanjing Special Motor Factory is available, which has large torque and can adapt to the frequent movement, and the large torque exceeds the rated torque by 2.4-3 times.

The reducer adopts a three-stage fixed-axis helical gear transmission mechanism. Gears and shafts are made of alloy structural steel or high-quality carbon steel and undergo heat treatment to ensure their reliability and life.

Thickened high-quality cast iron cover, processed by high-precision CNC lathe. The box body and the box cover hole position are accurately and perfectly matched, and well-sealed. It’s impact-resistant, waterproof, dust-proof, and oil-resistant.

The fire limiter can cut off the main circuit in case of emergency, which is fitted at the top and bottom ends to prevent the load chain from running out. It will protect when overload, over-current, loss of voltage or phase-off.

The thickened inner drum is made of cast iron or seamless steel pipe by high-temperature quenching using splines to transmit power which is wear-resistant and durable. The anti-off-rope outer real is welded with steel plates. Conforms to FEM standard.

The rope guide is made of stronger ductile iron and improves the service life. It makes the steel wire rope neatly arranged on the reel, prevents oblique pull, and avoids the mechanical failure of the electric hoist caused by improper operation.

Common Wire Rope Hoist Models

Liftpand can produce various non-standard wire rope electric hoists according to the samples and design drawings provided by customers to meet their different needs of customers.

Working of CD1 Electric Wire Rope Hoist

The lifting work principle of CD1 type electric hoist is:

power on the motor → open the conical brake → motor rotation → solid coupling → reducer → three-stage helical gear → drive the reel → drive the wire rope → hook up and down → power off the motor → close the brake → stop running

The drum device is the central part of the hoist, the upside is connected to the moving part by the balance beam, and the two ends are respectively connected to the hoisting reducer and the motor, and the downside is connected to the hook device through the wire rope. A limiter guide rod device is installed on the front top of the outer reel cover.

Difference of CD1 & MD Electric Wire Rope Hoist

CD1 type wire rope hoist only has one lifting motor. But MD has two motors.

The lifting speed of the CD1 electric hoist is normal speed, which can meet the general use requirements; the MD1 electric hoist has two kinds of lifting speeds – normal speed and slow speed. When working at a slow speed, it can meet the requirements of precision loading and unloading, sandbox mould closing, machine tool maintenance and other fine operations. Therefore, the range of use of the MD1 electric hoist is wider than that of the CD1 electric hoist.

So MD1 is a little expensive than CD1.

- Manufacturing Photos of CD1

- Technical Data

Related Product

It includes the lifting framework, travelling framework, and electric apparatus control system.

The electric lines are all debugged before leaving the factory. After receiving the goods, they need simple assembly and jointing of the wire ends before they can be used.

Once any questions, welcome to contact us.

There is stock of our standard hoist. If require wire rope length above 12M, it will take about 3days. If non-standard, it will take at least one week.